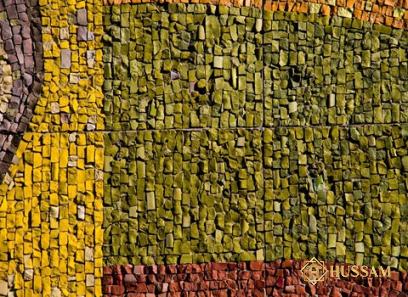

12×24 limestone tile is a highly recommended tile for distribution as it is offered in different colors such as brown, tan, and black. Natural stone is a product of nature and no two pieces are the same. These codes are intended as a general guide to the variation in color, movement, and texture that can be expected. All natural gemstones have unique natural variations and inclusions that cannot be shown in photographs or samples. For this reason, all stones should be unpacked and inspected prior to installation, as Marble Systems will not accept any claims for any stone changes after installation.

- Some medium and heavy duty stones cannot be used for exterior applications in areas subject to freeze-thaw conditions. Please use the specific stone in the user guide for this information. Some medium sized stones may be scratched or etched when used as countertops.

- Light, medium and heavy traffic refers to pedestrian traffic only. If you are installing the stone in an area of vehicular traffic, please contact your sales representative for thickness and installation requirements.

- If used in wet areas, stones in this group should be sealed regularly as part of a normal maintenance procedure.

- These materials may contain open or dry seam areas that may appear dull in reflected light. This is not a defect, but an inherent property of the stone.

- Requires a white sheet or mortar. This applies to all limestones, rolling stones, “old stones” and light colored marbles.

- These stones can be characterized by dry seams, pits and fossils. In polished and honed stones, these areas are usually filled at the factory. In rustic or tumbled stone and some polished limestones, these are usually filled with grout during installation. The filler can be drained from the vacuum, whether filled at the factory or during installation. In these cases, these voids may need to be filled as part of normal maintenance procedures.

12×24 limestone tile distribution

12×24 limestone tile is used for different places. Due to this fact, the distribution of this type of tile makes a profitable job. It’s easy to make your kitchen, bathroom, or anywhere else spotless with our limestone tiles. Marble Systems limestone tiles and mosaics are quality products for any space. One of the reasons this stone is so popular is that it is easy to maintain with just a little soap and water! It looks natural in any use – especially in outdoor spaces like kitchens, bathrooms, or patios – and wears well. With refined finishes, your space will be more than magnificent. It also offers less glare and gives you silky smooth vision! Nowhere else will you find the elegance of beige limestone tile to suit your space. Giving you a variety of coordinating wall, floor, and mosaic tile options for design flexibility during installation, your walls are sure to look beautiful. This product measures 12x24x3/8. This product may be available in different sizes. Please use our website to search for different size options. Limestone tiles are made from natural stone and are one of the most affordable options if you want to avoid synthetic materials for your floors. Limestone is a better deal than something like granite or marble. When shopping for limestone tiles, you will also find a variety of prices, ranging from less than $4 per square foot to $12 per square foot. The appearance of limestone is one of the reasons it is so prevalent. It’s soft and lightweight, delivering a warm, earthy tone no matter where it’s placed. This makes it particularly attractive for outdoor spaces. But limestone looks great in kitchens, bathrooms, and anywhere you want to brighten up with natural stone.

12×24 tile distribution

There are different proper sized for distribution such as 12×24, 8×8, and 6×6. All tiles displayed on this website are presented as nominal tile sizes. The nominal size is the intended production size of the tile plus the joint size. For example, a tile with a nominal size of 600 x 600 mm typically has a production size of 597 x 597 mm (+3 mm seam width). Unless tiles are ground (mechanically cut to exact size), tolerances for production dimensions are approximate +/- 2mm. The edges of the straightening tiles have been cut or mechanically ground to maintain uniformity, ensuring tiles are exactly the same size across the entire product line. This allows the fixture to firmly hold the tiles with minimal grout joints. Patch tiles are easier to use when installing unique tile patterns and designs due to their precise dimensions. Uncorrected tiles that do not have uniformly calibrated edges require wider grout joints so differences between tiles are not visible. With advances in tile production technology, tiles can be produced in increasingly larger sizes and in varying thicknesses. Tile sizes over 3 meters can now be produced with special shipping and fixing requirements, Solus can advise. Solus offers many large formats tile options, some of which can be viewed in our Clerkenwell showroom. Tile thicknesses of 20mm can be produced making them suitable for use in exterior dry lay systems. These tiles are very strong and have good anti-slip properties for use in wet outdoor conditions. Use the Tile Finder to view a selection of 20mm outdoor tiles or call the sales team who will be happy to explain the full range to you. In addition to the many standard tile sizes available, Solus also offers a tile cutting service that allows the tile to be cut and supplied in any size, giving designers unlimited creative uses for tile. For more information, you can contact our technicians by filling out a form.

tan limestone tile

we offer our customers the tan limestone tile which is cut and machined in a number of different finishes.

- Honed – A rigid matte finish with sharp edges.

- Tumbled – A worn, worn/weathered, bleached look with rounded edges.

- Polished – Shiny reflective surface with sharp edges.

- Brushed – A smooth textured surface with rounded edges – Brushed retains more of the tile’s original color than tumbled.

In the market, polished limestone tiles are the most popular, followed by the barrel, polished, and brushed. There are a few other finishes like “Pillow”, but these are really niche products, and processing this finish in the factory is time-consuming and expensive, with a ripple effect on the cost when it hits the shelves. Many limestone tiles have a polished finish, but the degree of polish depends on the density of the stone. Soft limestone does not require polishing like a very hard stone, and if someone travels, the polished surface of soft limestone will wear off in a short time. That’s why we don’t recommend using our polished Mediterranean White Limestone tiles on living room floors unless you’re willing to polish them from time to time. Rolled limestone tiles work best on older properties, although rolled tiles can look good when used with modern furniture when done right. The marble and limestone tiles from the middle east are known to be the hardest. However, be aware that some of these factories may have been nearby when Jesus walked the earth, and the quality may be inconsistent, to say the least, so if you end up choosing stone from the region, be sure to buy quality tiles!

Tan tile distribution

Tile distribution increases rapidly as using ceramic tiles with different colors such as black, marble, tan, and brown grow up. Due to the way the tile market has developed, the journey of tiles to the end user is different from that of other floor coverings. In the beginning, there were tile stores and carpet stores, each of which has matured its own supply chain. After all, rugs are mostly made by international manufacturers, while tiles are often imported from Italy, Spain, Mexico, or China by distributors who then sell them to tile shops, independent retailers, or to wholesalers. Over time, both entities began to enrich their product lines with additional floor coverings. However, their supply chains remain largely the same – separate from each other. When home improvement centers appeared, they added a new dimension to the tile trade. They sourced low-cost materials mostly from overseas, raising the profile of tiles as an affordable and hard-wearing flooring option and becoming a powerhouse in volume. However, because they order directly from the source, import the material themselves, and distribute it through a dedicated network, they move the tiles from source to end user without the help of an independent distributor. For a variety of reasons, mostly proprietary, some major international manufacturers also distribute wholly or partially internally in an effort to control their supply chain, selling directly to A&D or to independent retailers themselves via showrooms. These manufacturer-distributors and home centers, which are direct selling groups, account for 65% of all tiles sold in the international market. Another 20% of the market are tile dealers who import tile or buy directly from international manufacturers and sell that product to independent retailers. Another 15% of international products are sold by independent wholesalers who sell tile directly to specifiers or end-users through company showrooms.

12×24 tile

Gone are the days when 12×24 tiles were only used in bathrooms. However, thanks to innovative patterns, textures, and designs, these tiles are now used in almost all types of places including kitchens, bathrooms, living rooms, and bedrooms. Therefore, these tiles are not only popular in domestic settings but also widely used in commercial spaces. However, 12×24 tiles are more difficult to install than normal 12×12 tiles. However, with a little preparation and following some of the tips provided below, you can quickly install these tiles even if you have no previous experience. Review and follow the tips provided below to make your tile installation experience as enjoyable and memorable as possible. 12 x 24 tiles are everywhere these days. It seemed like a fun, more modern option when we installed it in our bathroom a few years ago, but now it seems to be the norm for new tile floors everywhere. I’ve seen it used a lot in commercial applications and in many homes, and it doesn’t look like it’s going anytime soon. I really like the look and durability of a 12×24 tile floor, so I really think it’s a good choice. However, it is a bit more complicated to install than the more traditional 12×12 tiles. Getting (and maintaining) the whole level is just about the biggest challenge when working with giant tiles like this. You’ll want to level each individual tile, but you’ll also want to make sure all tiles are placed evenly on the mortar and at the same height as each other. Before you start, make sure you have a small spirit level of about 24 inches so you can check how each tile is placed.

Your comment submitted.